5KG/5L Advance Pilot Spray Dryer, air pressure/high speed centrifugal

SD-05A

SD-05A Pilot Spray Dryer is based on the original test spray dryer of LABFREEZ

Product info

Product introduction

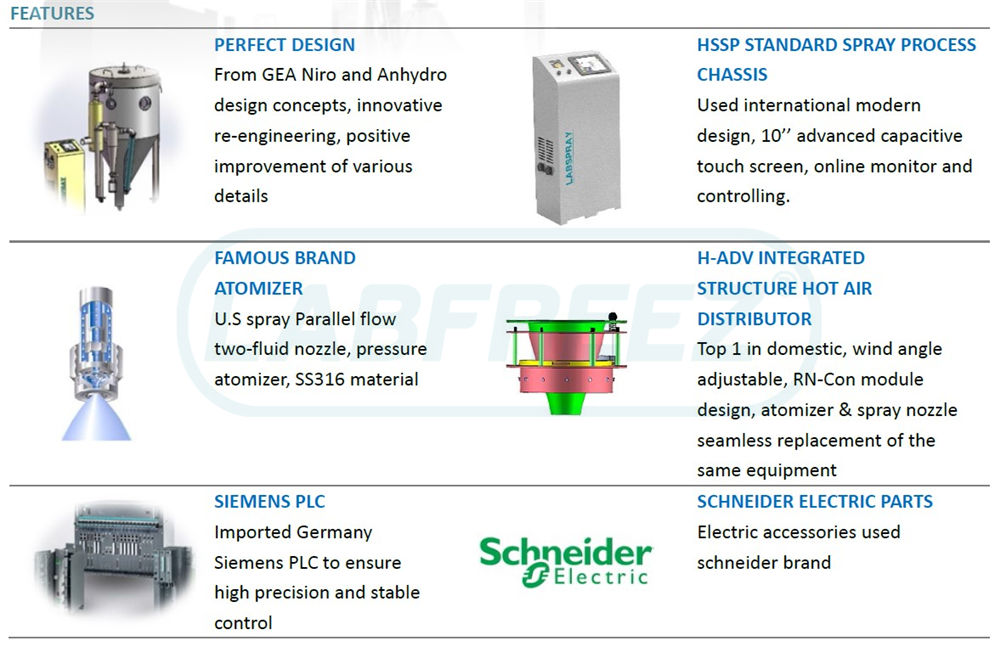

SD-05A Pilot Spray Dryer is based on the original test spray dryer of LABFREEZ, through a large number of research and learn from the Danish GEA Niro and Anhydro spray dryer design concept, and the newly developed upgraded version of the pilot type spray dryer. Among them, SD-05A has a stable appearance, beautiful atmosphere, convenient operation, patent shape design, high quality technology level and new control system, which meets the needs of more laboratory and pilot users, and even can replace the imported spray dryer

Application.jpg)

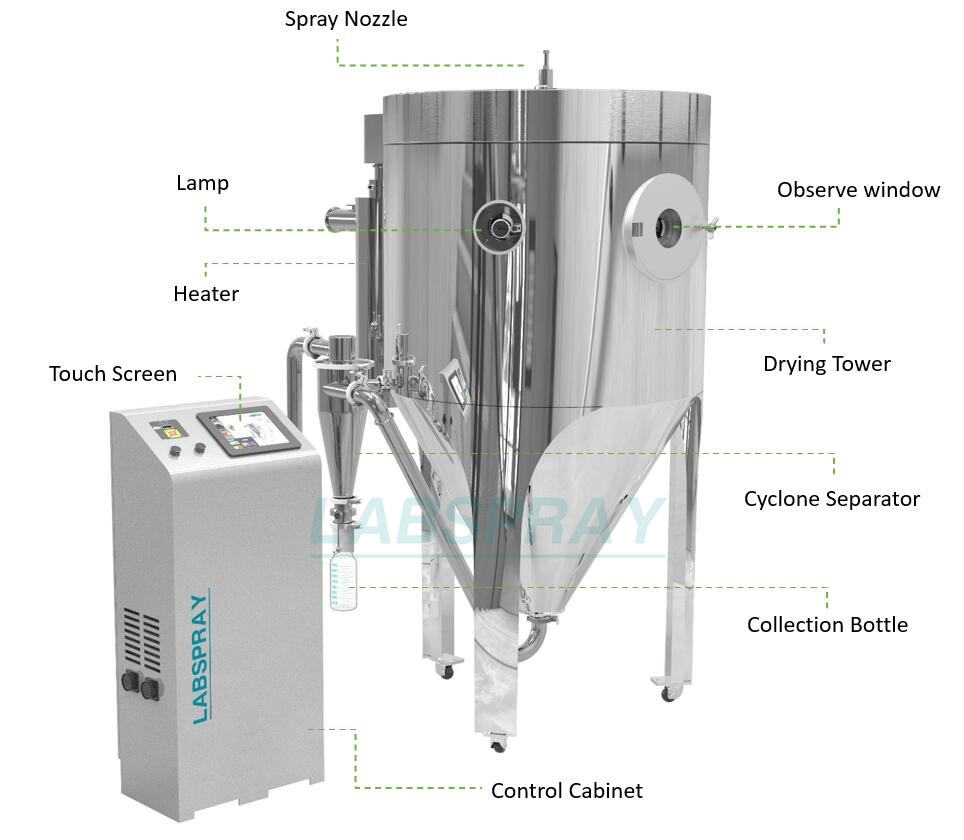

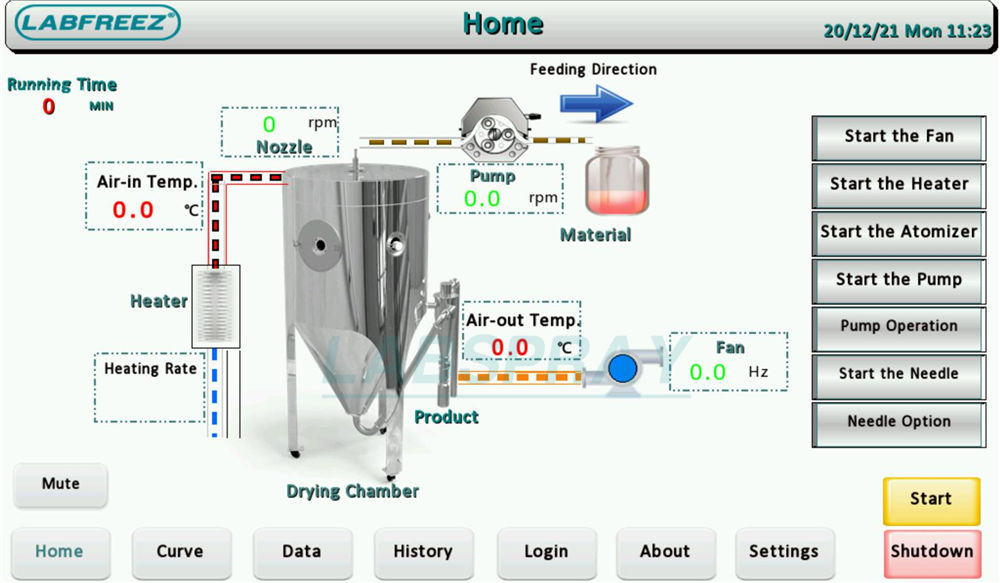

Process Description

- SD-05A has been introduced to meet the still increasing demand for a more flexible, modern and easy-to-handle laboratory dryer having different levels of control systems. The sanitary design, the easy access to all internal surfaces and the range of available options for optimizing the configuration will be appreciated by all users

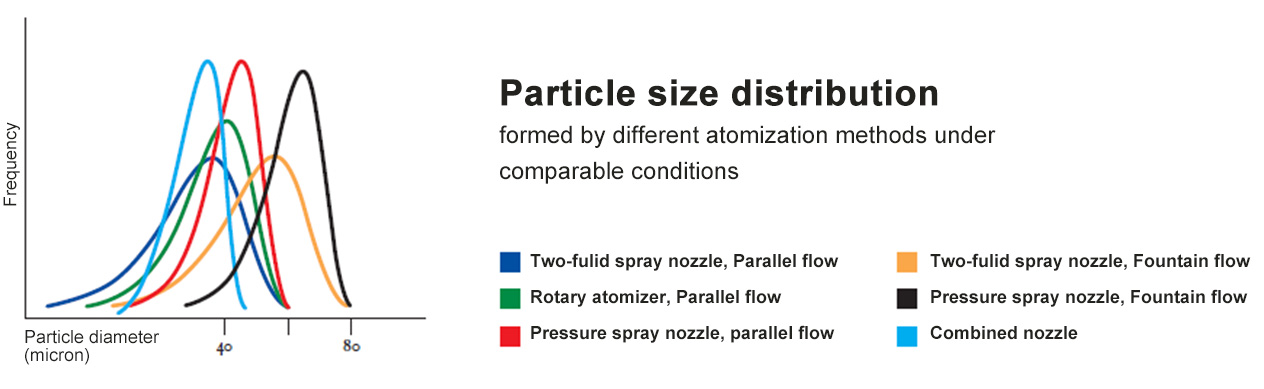

- The liquid RN-Con feed is atomized by a two-fluid nozzle co-current or, alternatively, by an centrifugal atomizer.

- The drying gas is heated by means of electricity, and enters the chamber via a specially LS-Adv designed gas distributor.

- The drying chamber has a conical bottom with a 60゜cone angle. The chamber is provided with WD door, light and sight glass.

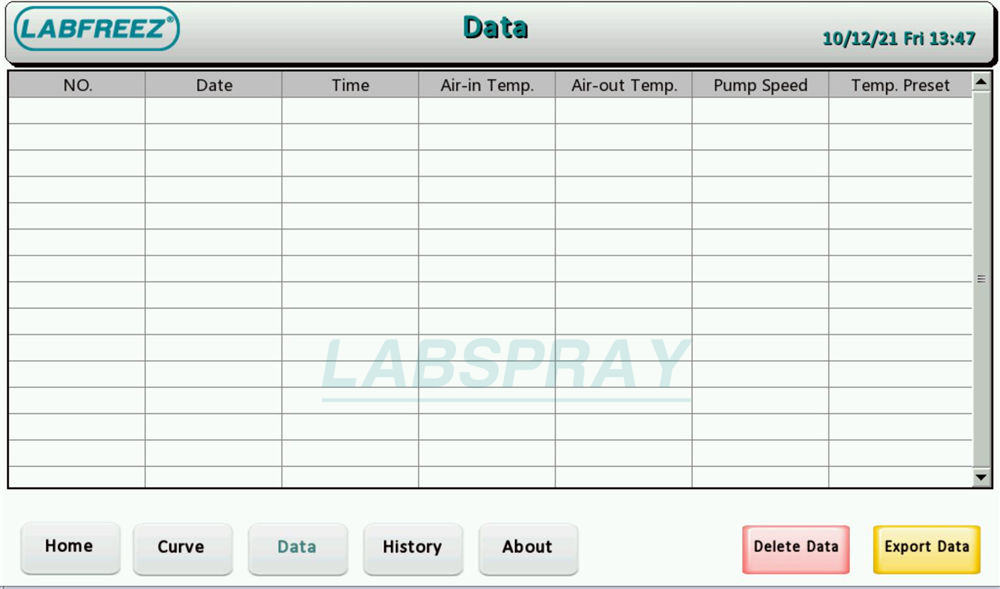

- The plant is delivered with an PLC including necessary control and instrumentation.

Materials of Construction

- The plant will be delivered in sanitary execution according to Food hygiene standards. All metallic parts in contact with the process, product or gasses are made in stainless steel AISI 304.

- External surfaces and welding are polished to Ra < 1.2 µm.

- Internal welding in product contact parts (drying chamber, powder duct, cyclone, powder container, gas duct to bag filter) have smooth surfaces, max. Ra0.8µm. Sand blasting technology on the outer surface.

- Other internal welding are ground flush to parent sheet grit 120.

- Stainless steel cladding is made in AISI 304.

Main Components

- Feeding Pump

- Two-fluid Nozzle Atomizer

- Centrifugal Atomizer (option)

- Delivery Fan

- Gas Heater

- LS-Adv Gas Distributor

- Drying Chamber

- Cyclone

- Field Instrumentation and Control System Hard Ware

Technical Parameters

Optional Accessories

Intelligent Silent Oil-free Air Compressor (oPTIONAL)

- Pure oil-free: pure oil-free design, the output gas does not contain oil molecules, no harm to the human body

- Ultra-quiet: low noise, smooth and non-fluctuating output air pressure, reducing noise pollution

- Multi-stage filtration: multi-stage gas filtration, cleaner and purer, extending the service life of the instrument

- Internal spray rust prevention: The gas tank is finished by internal spraying to prevent the air from being rusted and contaminated.

- Safe to use: If the voltage and current cause the machine to overheat, automatically stop the protection to avoid burnout.

- Automatic start: intermittent use, machine switch does not need to be restarted

- Adjustable air pressure: air pressure can be adjusted to meet different equipment needs

- Durable: used according to regulations, using more than 15,000 hours

- Simple maintenance: no need to add lubricant, easy to maintain after purchase

.jpg)

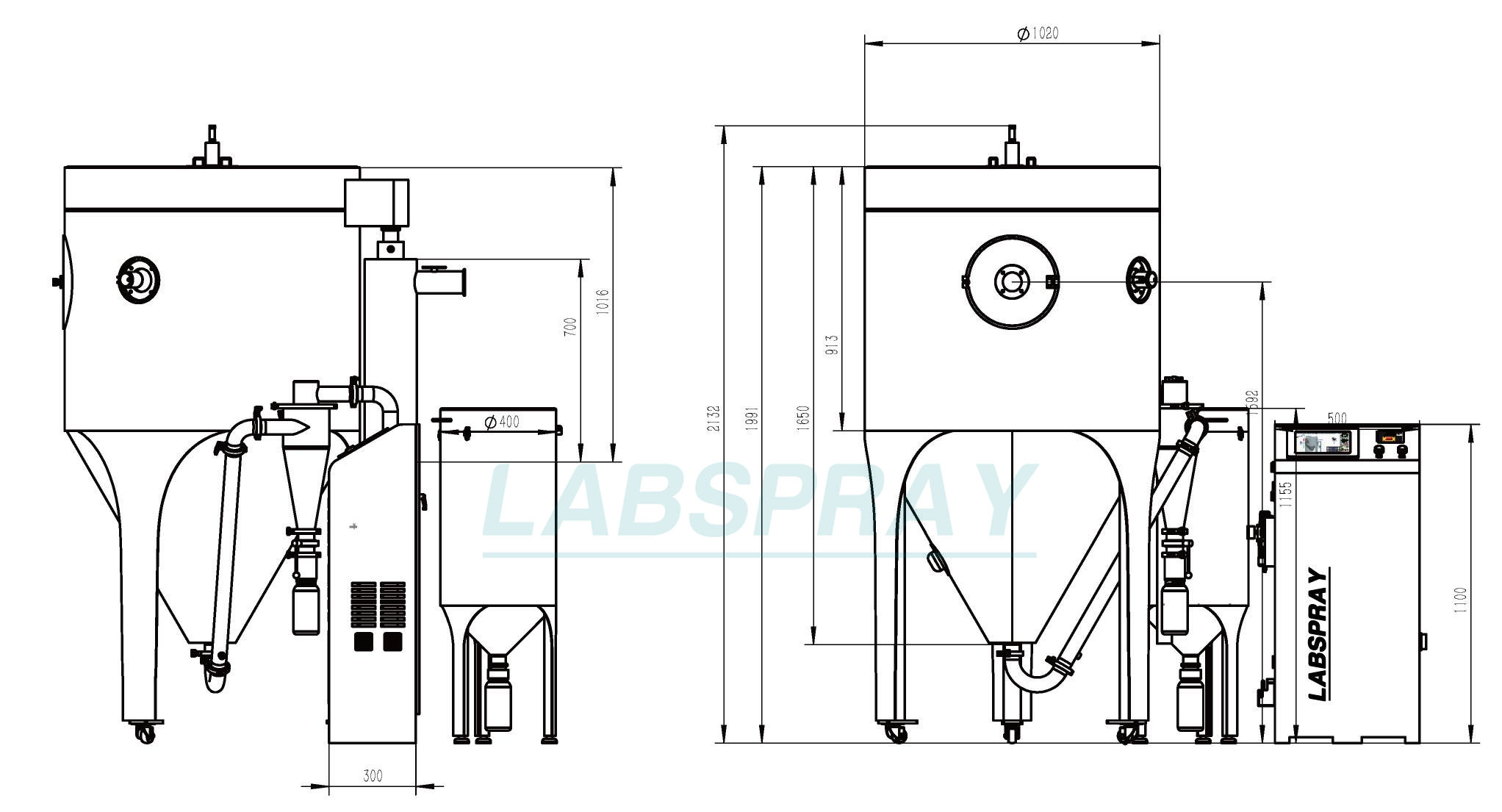

Layout size

_1.jpg)